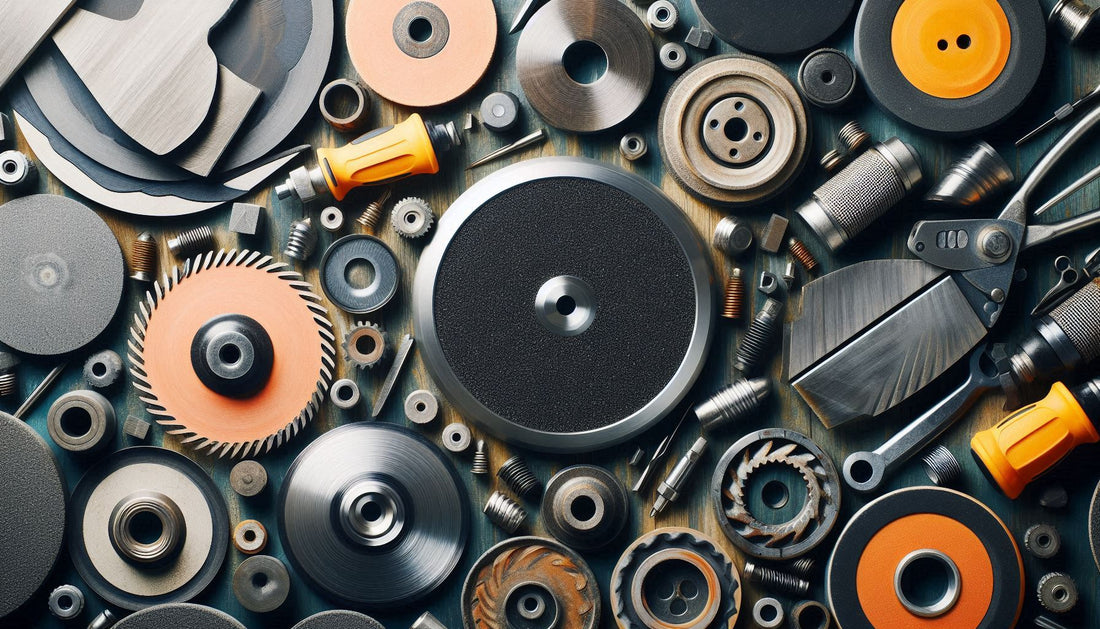

When it comes to metalworking and fabrication, having the right tools for the job is essential. Cutting discs and grinding wheels are two common abrasive tools used in various industries for cutting, grinding, and finishing tasks. Let's explore the different types of cutting discs and grinding wheels available in the market.

What are Cutting Discs?

Cutting discs, also known as cutting wheels or abrasive discs, are used for cutting various materials such as metal, steel, stainless steel, and aluminum. These discs are typically thin and reinforced with fiberglass mesh to provide strength and durability during cutting operations. They come in different diameters and thicknesses to suit different cutting applications.

Types of Cutting Discs:

1. Metal Cutting Discs: Designed for cutting metal and steel, these discs are made with aluminum oxide or silicon carbide abrasives.

2. Diamond Cutting Discs: Ideal for cutting hard materials like concrete, tiles, and stone, diamond cutting discs have diamond particles embedded in the disc for superior cutting performance.

3. Ceramic Cutting Discs: Used for cutting ceramic tiles and other brittle materials, ceramic cutting discs are made with a ceramic abrasive grain.

What are Grinding Wheels?

Grinding wheels are abrasive wheels used for grinding, shaping, and finishing metal, steel, and other materials. These wheels are composed of abrasive particles bonded together with a bonding agent to form a wheel structure. Grinding wheels come in various shapes, sizes, and abrasive materials to suit different grinding applications.

Types of Grinding Wheels:

1. Aluminum Oxide Grinding Wheels: Commonly used for grinding steel and other ferrous metals, aluminum oxide grinding wheels are versatile and durable.

2. Silicon Carbide Grinding Wheels: Ideal for grinding non-ferrous metals, stone, and glass, silicon carbide grinding wheels offer fast stock removal and excellent surface finish.

3. Diamond Grinding Wheels: Used for grinding hard materials like carbide, ceramics, and glass, diamond grinding wheels provide superior grinding performance and long service life.

Choosing the right cutting disc or grinding wheel for your specific application is crucial for achieving the desired results. Consider the material to be cut or ground, the required finish, and the machine compatibility when selecting the appropriate abrasive tool. Always follow safety guidelines and manufacturer recommendations when using cutting discs and grinding wheels to ensure safe and efficient operation.